The Hidden Cost of Building in 2022

As the need for new housing in Ireland becomes more urgent by the day, we face a dilemma. On one side is a housing crisis, on the other is rapidly accelerating climate change. We must dramatically increase the rate of construction, while minimising greenhouse gas emissions. Unfortunately, buildings are responsible for approximately 36% of carbon emissions in the EU, since the construction industry relies heavily on energy input from fossil fuels (1). Globally, concrete production is responsible for five percent of total CO2 emissions every year. Vast quantities of fuel are burned to produce concrete including: natural gas, fuel oil, waste tires, liquid and solid wastes. These solid wastes used include plastics you have sent for recycling. Additionally, electricity is consumed in the mixing and grinding of the concrete, not to mention the shredding of tires and other solids for fuel. All this material when burned releases particulate matter, nitrogen oxides, and sulfur dioxide. Additionally, carbon monoxide, volatile organic compounds, and toxic emissions (e.g., heavy metals, dioxins, and furans) are released.

The carbon generated in the construction of a building is its “embodied carbon”. This refers to emissions from extracting and transporting materials, constructing buildings, and eventually demolishing them. This embodied carbon can represent up to 70% of the building’s carbon emissions over its lifetime. Clearly, something must change. The need for properly sustainable building materials is urgent. Thankfully, there are many options available to us to lower the carbon emissions of our buildings.

Choosing more sustainable materials for building can drastically reduce the embodied carbon of a building:

- Timber (especially from sustainably managed forests).

- Clay and rammed earth (locally sourced).

- Repurposed materials (salvage and reclaimed concrete, brick, timber).

- Plant-based materials (hemp, bamboo, straw bales, cork).

Read more about ZWAI’s stance on the contribution of the construction industry to climate change in our presentation at the National Construction Summit.

Hempcrete may be a Sustainable Solution

Hempcrete is an exciting concrete alternative which is carbon negative. The hemp plant absorbs CO2 from the atmosphere as it grows, so the hempcrete is considered a carbon storing material. The material is made from hemp hurd, which is the tough inner woody material of the hemp stalk, left over once the fibre is removed. These chips are mixed with builder’s lime to produce a solid building block. The lime protects the plant material from breakdown by micro-organisms and fungi, meaning the CO2 is potentially locked away for hundreds of years. Additionally, the hempcrete blocks absorb more CO2 from the air as they age, through carbonation. Read more about this in the Journal of Cleaner Production.

Hempcrete even acts as insulation, reducing the energy needed to keep the home warm in winter or cool in summer. All this means that choosing hempcrete over concrete can dramatically reduce the embodied CO2 of the building, assuming the hemp hurd is not transported long distances to the construction site, and the lime is sustainably produced (2).

Advantages of Hempcrete:

- Fire-resistance: The lime binds to the hemp material and protects it from fire.

- Carbon capturing: The blocks absorb more Co2 from the air as they age through carbonation.

- Lightweight: 275kg/m3, compare with concrete at 2400 kg/m3!

- Insulating: Pockets of air in the material, plus microscopic pores in the hemp hurd results in good insulating properties. The material also provides thermal mass, meaning it acts like a giant storage heater.

- Absorbs more CO2 over time: This is a property of the lime binder. On average 23–33% of lime process emissions are re-absorbed throughout its lifecycle! (3)

- Compostable: At the end of its life, the hemp and lime mix can be added to fields or gardens to improve the soil

Disadvantages of Hempcrete:

- More expensive than concrete: $135 per m2 for hempcrete, $75 per m2 for concrete

- Not load bearing: The structure must be supported by timber frames or other materials.

- Might not be available everywhere: Limited to regions with the proper climate to grow hemp.

Company Spotlight: “Just Biofibre” – Sustainable or Suspicious?

This company produces Lego-style hempcrete blocks with an internal structural composite frame. This frame is load bearing, so it eliminates a major disadvantage of regular hempcrete blocks. The product certainly looks promising at first glance.

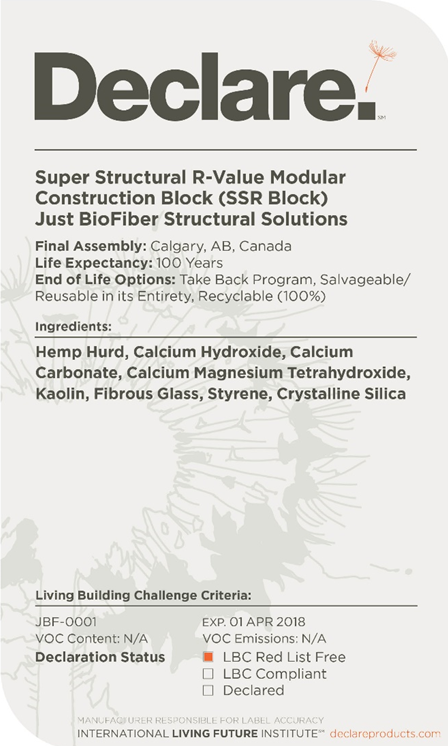

Just Biofiber president Terry Radford claims the blocks contain a “bio composite” and they apparently do not contain plastic. However, after a quick look at their website, I found the image below which lists the ingredients of the blocks. The stated ingredients for the “bio-composite” are fibrous glass and styrene, the base material for polystyrene, AKA: Styrofoam. I reached out to Just Biofibre for more information on this inconsistency, but I didn’t receive a response.

Unfortunately, Styrene is an environmentally damaging petrochemical. It’s derived from crude oil benzene through a series of chemical reactions. It’s not considered biodegradable and is predicted to persist in the soil for many centuries, and is possibly carcinogenic (4).

If the internal composite material is made from styrene and glass fibre, it cannot be considered a “bio composite”. Just Biofibre’s site misleadingly proclaims the “structural composite” is “anything BUT plastic!”, Why not state exactly what it is?

In this video, Terry Radford claims the material is a “bio-composite” made from vegetable oil based polyester resins. He goes on to describe the material as “more of an epoxy than it is a plastic”. So, which is it? Styrene or polyester? Styrene may be considered a resin rather than a plastic in some circles, but it is still a fossil fuel- derived petrochemical that damages the environment.

All this inconsistency reeks of greenwashing, and unfortunately, I do not trust this company with all their claims of sustainability. The blocks are marketed as sustainable, but if they are roughly 50% glass fiber and petrochemical, it’s highly misleading.

This blog post by Endeavour Centre is quite revealing. They used the Just Biofiber blocks in the construction of a forensics facility. The blocks required a glue that is “smelly, toxic and messy”. Again, I haven’t seen mention of this glue anywhere on the Just Biofiber website or marketing, and its ingredients are also a mystery.

Despite the urgent need for sustainable building material, many companies try to greenwash their products to mislead customers about the sustainability of their materials. This takes market share away from legitimate sustainable companies and creates general confusion and mistrust. I think the best approach is to take claims of sustainability with a grain of salt and do your own research before purchasing.

“The world is in a race against time. We cannot afford slow movers, fake movers or any form of greenwashing”

UN secretary-General Antonio Guterres

Hemp Options in Ireland

- Roundtower Lime offers hemp hurd in 20kg bales for use in construction. However, it seems they can only supply the material and do not offer the equipment or expertise for incorporating hemp in constructions: www.roundtowerlime.com

- Hempbuild Sustainable Products Ltd can deliver ready made hempcrete blocks for external or internal insulation, or for wall construction supported with another load-bearing structure. The site contains lots of accurate information and gives detailed evidence of successful builds: www.hempbuild.ie

Jack Coffey is from Cork and graduated from University College Cork in 2018 with a degree in Applied Plant Biology, with a specialty in Camellia sinensis physiology. He later went on to pursue a postgrad in Bio Pharmaceuticals. You can follow him on LinkedIn.

References

- Zhang, C., Hu, M., Yang, X., Amati, A. and Tukker, A., 2020. Life cycle greenhouse gas emission and cost analysis of prefabricated concrete building façade elements. Journal of Industrial Ecology, 24(5), pp.1016-1030.

- Arrigoni, A., Pelosato, R., Melià, P., Ruggieri, G., Sabbadini, S. and Dotelli, G., 2017. Life cycle assessment of natural building materials: the role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. Journal of Cleaner Production, 149, pp.1051-1061.

- Natural and enhanced carbonation of lime in its different applications: a review

- Styrene on Wikipedia